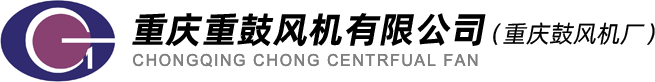

Anti-corrosion fan: GDF duct fan

The main components of the anti-corrosion fan are treated with anti-corrosion

Keywords: centrifugal fan supplier | general fan manufacturer

Classification:

Civilian general purpose fan

Hotline:

Anti-corrosion fan: GDF duct fan

The main components of the anti-corrosion fan are treated with anti-corrosion treatment or made of anti-corrosion materials, and the fans that can resist corrosion are collectively referred to as anti-corrosion fans. Anti-corrosion fans are widely used in ventilation, dust removal and odor extraction in factories, mines, electroplating, chemical industry, etching, and other places.

Anti-corrosion fan corrosion resistance: It is more corrosion-resistant than fans made of other materials, and can be used in special places with strong corrosion.

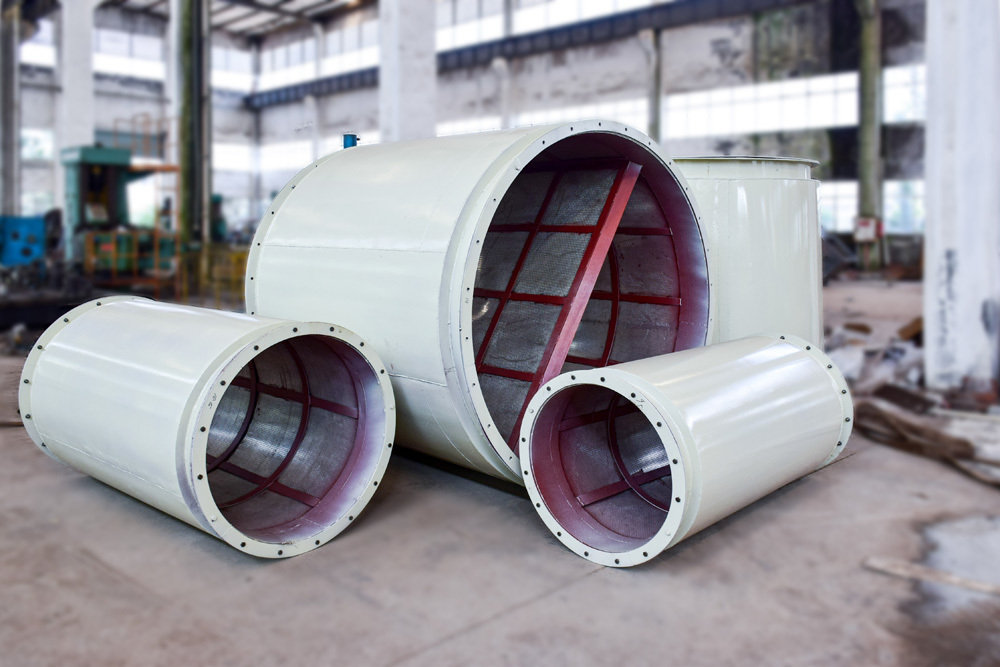

When the centrifugal anti-corrosion fan is working, the motor (motor) drives the impeller to rotate in the volute casing, and the air is sucked in from the center of the impeller through the suction port. Due to the dynamic action of the blades on the gas, the gas pressure and speed are increased, and under the action of centrifugal force, it is thrown along the blade path to the casing and discharged from the exhaust port.

The centrifugal anti-corrosion fan is mainly composed of an impeller and a casing, and the impeller of the small fan is directly installed on the motor, and the medium and large centrifugal anti-corrosion fans are connected with the motor through a coupling or a pulley. Centrifugal anticorrosive fans are generally single-sided air intake with single-stage impellers; The large flow rate can be inlet on both sides, with two back-to-back impellers, also known as double-suction centrifugal anticorrosive fans.

When the axial anti-corrosion fan is working, the motor drives the impeller to rotate in the cylindrical casing, and the gas enters from the collector, and the energy is obtained through the impeller, which increases the pressure and speed, and then discharges it along the axial direction. There are three types of axial flow fans: vertical, horizontal and inclined, with a diameter of only about 100 mm for small impellers and more than 20 meters for large ones.

Small low-pressure axial flow anti-corrosion fans are composed of components such as impellers, casings and collectors, and are usually installed on the walls of buildings; The large high-pressure axial flow anti-corrosion fan is composed of a collector, an impeller, a streamline, a casing, a diffusion cylinder and transmission components. The blades are evenly arranged on the hub, and the number is generally 2~24. The more blades, the higher the wind pressure; The blade installation angle is generally 10°~45°, and the larger the installation angle, the greater the air volume and wind pressure.

The development trend of anti-corrosion fans

(1) Further improve the pneumatic efficiency, device efficiency and use efficiency of the anti-corrosion fan to reduce power consumption;

(2) Replace the large centrifugal anti-corrosion fan with an axial flow anti-corrosion fan with adjustable moving blades;

(3) Reduce the noise of anti-corrosion fans;

(4) Improve the wear resistance of the impeller and casing of the smoke and dust exhaust ventilator;

(5) Realize variable speed adjustment and automatic adjustment.

Prev

Chongqing blower: GDF duct fan

Chongqing blower manufacturing

Message consultation

Filling in your phone and E-mail information will help us to get in touch with you in time and solve your problems as soon as possible.