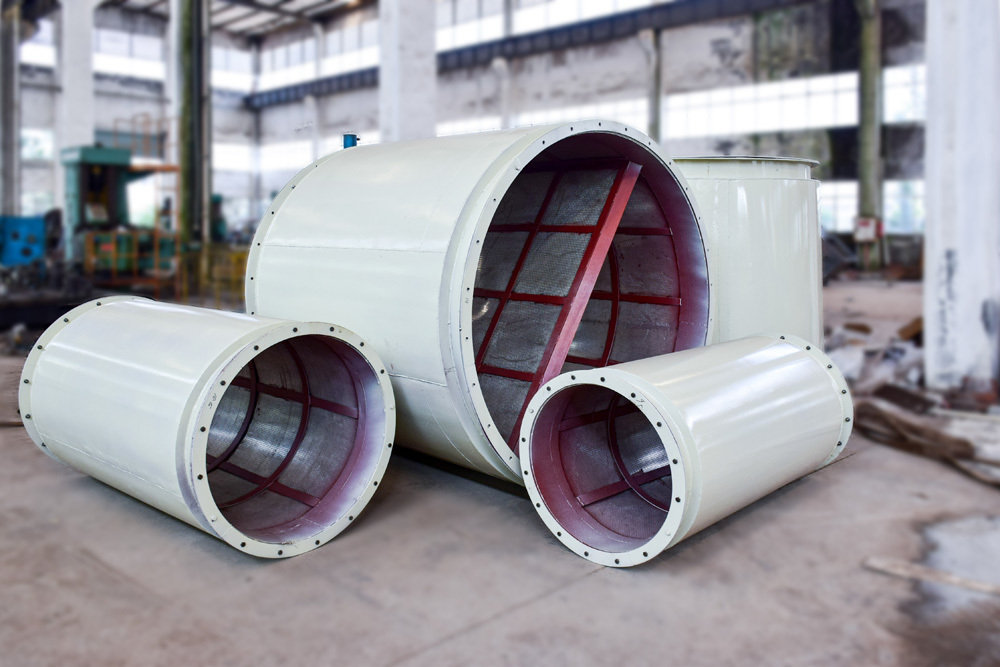

Fire smoke exhaust fan box: HLF-6 low noise mixed-flow fan box

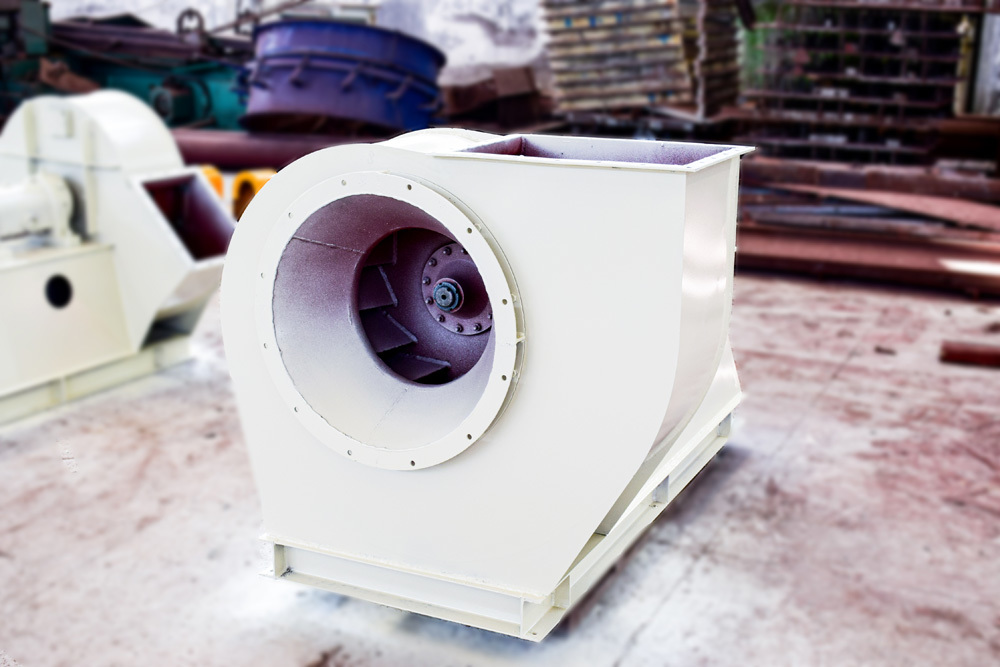

HTF fire smoke exhaust fan is HTF (A) series fire smoke exhaust fan

Keywords: centrifugal fan supplier | general fan manufacturer

Classification:

Civilian general purpose fan

Hotline:

Fire smoke exhaust fan box: HLF-6 low noise mixed-flow fan box

HTF fire smoke exhaust fan is HTF (A) series fire smoke exhaust fan, which adopts CAD software multi-objective optimization design, optional molded axial flow impeller, built-in high-temperature motor, and special motor cooling system. The two-speed motor is directly connected to the transmission to achieve a dual-purpose machine (that is, high-temperature smoke exhaust during normal ventilation and fire fighting), and it can be remotely and automatically controlled after being equipped with an electric control box.

This series of smoke exhaust fans has the advantages of excellent high temperature resistance, high efficiency, small size, and easy installation (horizontal, vertical, and hoisting).

HTF fire smoke exhaust fans are widely used in high-rise buildings, drying rooms, underground garages, subways, tunnels and other occasions for fire smoke exhaust and ventilation. According to the GA211-1999 fire fan high temperature resistance test method, it can run continuously for more than 100 minutes under the condition of 400 °C high temperature, and can run continuously for 20 hours / time under the condition of medium temperature 100 °C without damage, and has been recognized by the fire departments of major cities across the country. This series of fans can be equipped with a sound-absorbing box according to the requirements of installation and use occasions to make HTF(A)-X box-shaped fire smoke exhaust fans.

HTF fire smoke exhaust fan installation process

1. Be fully familiar with the sample of the fan, be familiar with the specifications, form, direction of rotation of the impeller and the direction of air flow in and out of the fan, etc., check whether the impeller has any friction phenomenon before the installation of the fan, and conduct a comprehensive inspection of each component, whether the accessories are complete, whether the connection of each component is firm, and carefully check whether the fan blade is damaged or deformed due to transportation, otherwise it should be installed after repair.

2. The air duct connecting the inlet and outlet of the fan should have a separate support, and the weight of the pipe is not allowed to be added to the parts of the fan.

3. After the fan is installed, pull the impeller by hand or lever to check whether there is too tight or rubbing, whether there are items that hinder the rotation, and there is no abnormal phenomenon before the test run can be carried out. If the air inlet of the fan is not connected to the pipe, it is also necessary to add a protective net or other safety device (provided by the user).

4. The wiring of the fan must be correct and reliable, and the shell of the fan should be properly grounded, and the grounding must be reliable. The power supply to the fan must be complete and meet the relevant requirements. Electrical wiring must have an electrician with specialized knowledge of wiring.

Product Description:

Prev

High-efficiency and energy-saving fan: HLF-6 low-noise mixed-flow fan box

Chongqing blower manufacturing

Message consultation

Filling in your phone and E-mail information will help us to get in touch with you in time and solve your problems as soon as possible.