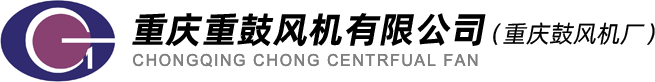

Fan manufacturing: intermittent GDF duct fan

Fan manufacturer: Fan is a machine that relies on the input

Keywords: centrifugal fan supplier | general fan manufacturer

Classification:

Civilian general purpose fan

Hotline:

Fan manufacturing: intermittent GDF duct fan

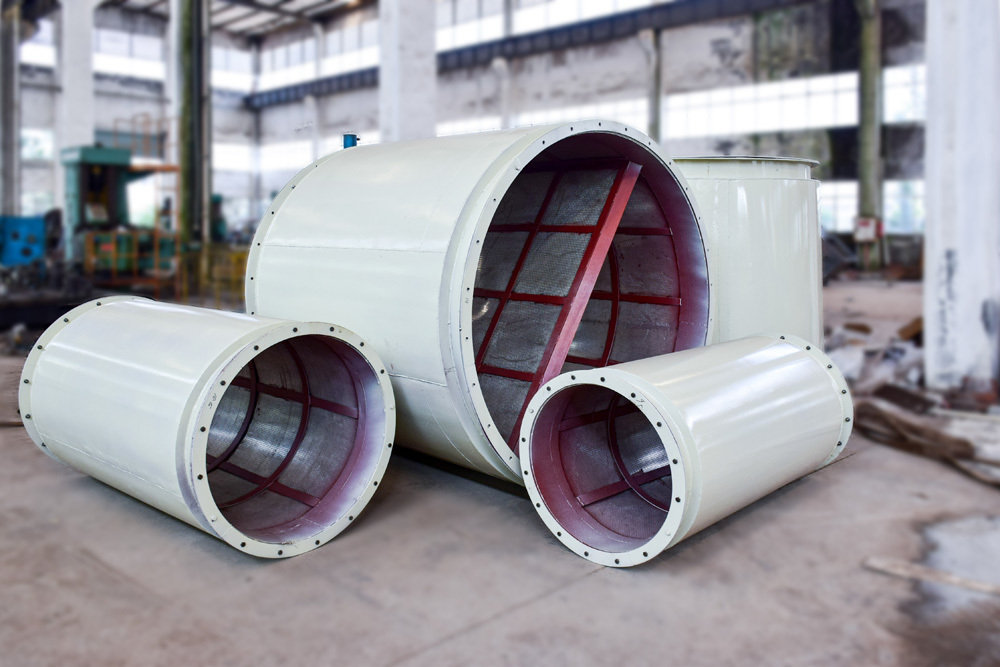

Fan manufacturer: Fan is a machine that relies on the input of mechanical energy to increase the gas pressure and discharge the gas, and it is a driven fluid machinery. Fans are widely used for ventilation, dust removal and cooling in factories, mines, tunnels, cooling towers, vehicles, ships and buildings; ventilation and induced air in boilers and industrial furnaces; cooling and ventilation in air-conditioning equipment and household appliances; drying and selection of grains; Wind tunnel wind source and hovercraft inflation and propulsion, etc.

Fan manufacturer: The working principle of the fan is basically the same as that of the turbine compressor, but due to the low gas flow rate and the small change in pressure, there is generally no need to consider the change of gas specific volume, that is, the gas is treated as an incompressible fluid.

Fan manufacturer: Fan classification

According to the direction of gas flow, the classification of fans can be divided into centrifugal type, axial flow type, oblique flow type and cross flow type.

According to the flow direction of the air flow into the impeller, the fan is divided into: axial fan, centrifugal fan and oblique flow (mixed-flow) fan.

According to the use, the fan is divided into press-in local fan (hereinafter referred to as press-in fan) and flameproof motor is placed outside or in the flow channel, and the flameproof motor is placed in the explosion-proof sealing cavity (hereinafter referred to as the extraction fan).

Fan manufacturer: fan performance parameters

The performance parameters of the fan mainly include flow, pressure, power, efficiency and speed. In addition, the magnitude of noise and vibration is also the main design indicator of the wind turbine.

The flow rate is also called air volume, which is expressed as the volume of gas flowing through the fan per unit time;

Pressure, also known as wind pressure, refers to the increase in the pressure of the gas in the fan, which is divided into static pressure, dynamic pressure and full pressure;

Power refers to the input power of the fan, i.e. the shaft power. The ratio of the effective power of the fan to the shaft power is called efficiency. The full pressure efficiency of the fan can reach 90%.

Wind turbine manufacturers: the future of wind turbines

The development of wind turbines will further improve the aerodynamic efficiency, device efficiency and use efficiency of fans to reduce power consumption; Replace large centrifugal fans with axial fans with adjustable moving blades; Reduce fan noise; Improve the wear resistance of smoke and dust exhaust fan impellers and casings; Variable speed adjustment and automatic adjustment are realized.

Prev

Fire smoke exhaust fan box: HLF-6 low noise mixed-flow fan box

Chongqing blower manufacturing

Message consultation

Filling in your phone and E-mail information will help us to get in touch with you in time and solve your problems as soon as possible.