Roots blower

The roots fan is a volumetric fan, with impeller end face

Keywords: centrifugal fan supplier | general fan manufacturer

Classification:

Industrial roots blowers

Hotline:

Roots blower

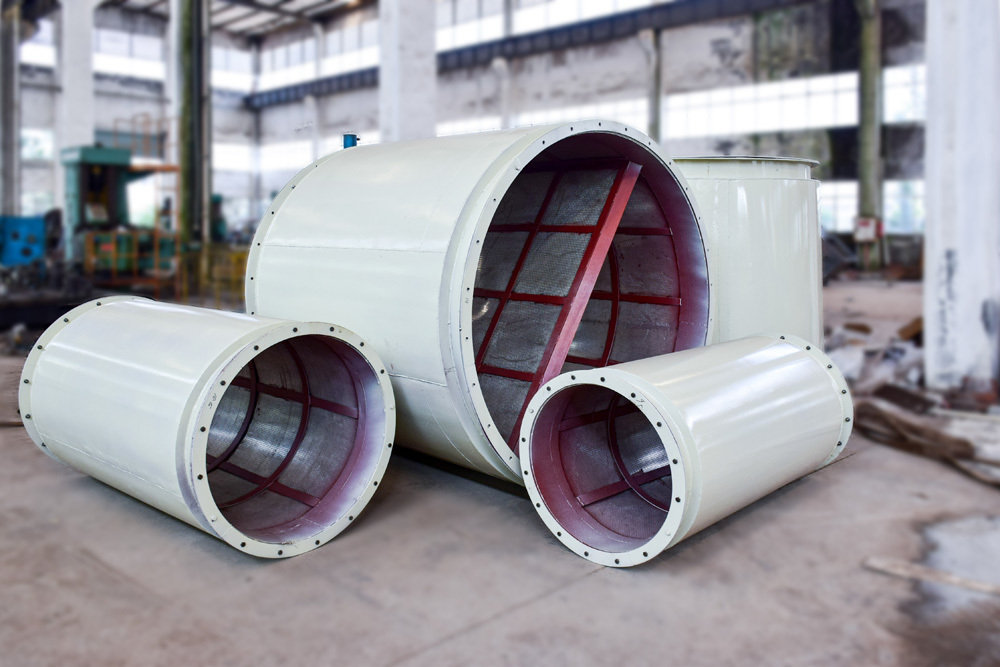

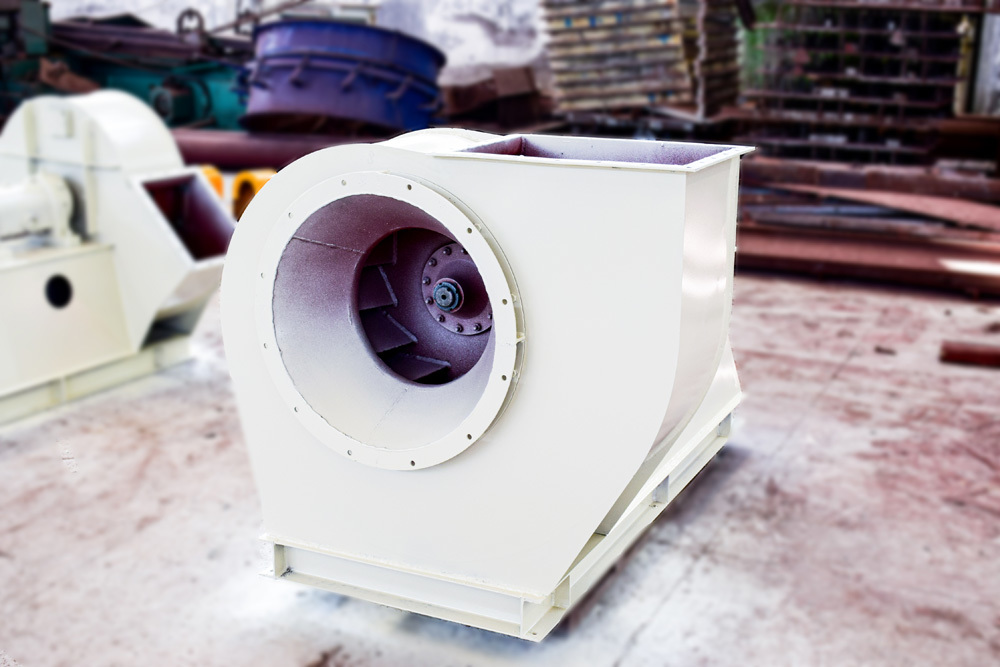

The roots fan is a volumetric fan, with impeller end face, front and rear end covers of the fan. The principle is a rotary compressor that uses two vane-shaped rotors to compress and transport gas in relative motion in the cylinder. This kind of blower has a simple structure and is easy to manufacture, and is widely used in aquaculture aeration, sewage treatment and aeration, cement transportation, and is more suitable for gas transmission and pressurization systems in low-pressure occasions, and can also be used as vacuum pumps.

The roots blower is composed of five parts: casing, wall panel, impeller, oil tank and muffler.

Chassis: mainly plays the role of support (wall panel, impeller, muffler) and fixation.

Wall panel: It is mainly used to connect the casing and the impeller, and support the rotation of the impeller, as well as to play the effect of end face sealing.

Impeller: It is the rotating part of the roots blower, which is divided into two lobes and three lobes, but due to the advantages of the three-lobe than the two-lobe gas outlet pulsation, less noise, and more stable operation, it has gradually replaced the two-lobe roots blower.

Oil tank: It is mainly used to store lubricating oil used to lubricate gears and bearings.

Muffler: It is used to reduce the noise caused by the air flow pulsation when the roots blower enters and exits.

Roots blower is a kind of positive displacement fan, there are two three-blade impellers in the space sealed by the casing and the wall plate relative rotation, because each impeller is the use of involute, or cycloid envelope, the three blades of each impeller are exactly the same, and the two impellers are also exactly the same, so that the processing difficulty is greatly reduced. The impeller adopts numerical control equipment during processing, which ensures that the two impellers can maintain a certain minimum gap no matter what position the two impellers rotate to under the condition that the center distance is unchanged, so as to ensure that the gas leakage is within the allowable range.

The two impellers rotate in opposite directions, because the gap between the impeller and the impeller, the impeller and the casing, the impeller and the wallplate is very small, so that the air inlet forms a vacuum state, and the air enters the air intake cavity under the action of atmospheric pressure, and then, one of the two blades of each impeller and the wallboard and the casing form a sealing cavity, and the air of the inlet cavity is continuously brought to the exhaust cavity by the sealing cavity formed by the two blades in the process of the impeller rotation, and because the impeller in the exhaust cavity is meshed with each other, the air between the two blades is squeezed out, In this continuous operation, the air is continuously transported from the air inlet to the air outlet, which is the whole working process of the roots blower.

Prev

None

Next

Chongqing blower manufacturing

Message consultation

Filling in your phone and E-mail information will help us to get in touch with you in time and solve your problems as soon as possible.